Introduction

In today's world, the reliability of power supply is crucial for ensuring the smooth operation of various systems and industries. From hospitals and data centers to manufacturing plants and residential buildings, uninterrupted power supply is a necessity to avoid disruptions and potential losses. One of the key components in ensuring system reliability is the diesel generator. Diesel generators are widely used as backup power sources in case of grid power failures or outages. In this article, we will explore the importance of diesel generators in enhancing system reliability, their key features, benefits, maintenance requirements, and best practices for optimal performance.

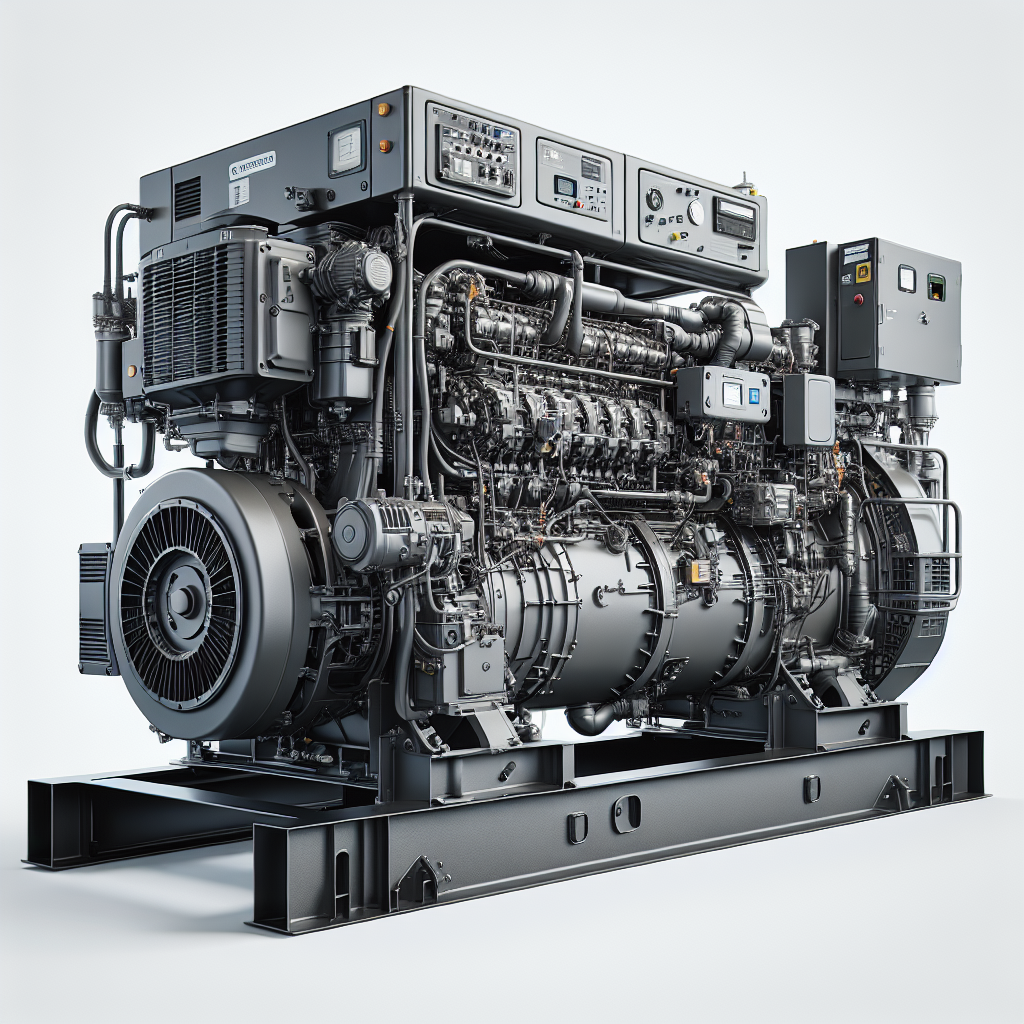

75kw diesel generator for remote engineering projects of Diesel Generators in Enhancing System Reliability

System reliability refers to the ability of a system to consistently deliver power or perform its functions without interruption. In many critical applications, such as hospitals, emergency services, and telecommunications, even a momentary power outage can have serious consequences. Diesel generators play a vital role in ensuring continuity of power supply during such situations. They act as a reliable backup power source that can quickly kick in when the main power supply fails, providing seamless transition and preventing downtime.

One of the key advantages of diesel generators is their ability to provide a high level of power output and reliability. Diesel engines are known for their robustness, durability, and ability to operate continuously for extended periods. This makes diesel generators well-suited for applications where reliability is paramount. In addition, diesel fuel is readily available and can be stored for long periods without deterioration, ensuring that the generator can be quickly activated when needed.

Key Features of Diesel Generators

Diesel generators are available in a wide range of sizes and configurations to suit different power requirements. They consist of several key components that work together to generate electricity when needed. The main components of a diesel generator include:

1. Diesel Engine: The diesel engine is the primary component of the generator that converts the chemical energy in diesel fuel into mechanical energy. Diesel engines are known for their efficiency, durability, and ability to provide high power output.

2. Alternator: The alternator is responsible for converting the mechanical energy generated by the diesel engine into electrical energy. It consists of a rotor and stator that produce an alternating current (AC) output.

3. Control Panel: The control panel of a diesel generator houses the necessary controls, switches, and indicators for starting, stopping, and monitoring the generator. It also includes safety features such as overload protection and voltage regulation.

4. Cooling System: Diesel engines generate a significant amount of heat during operation, which needs to be dissipated to prevent overheating. The cooling system of a diesel generator typically consists of a radiator, cooling fan, and coolant circulation system.

Benefits of Diesel Generators

Diesel generators offer several advantages that make them a popular choice for backup power applications. Some of the key benefits of diesel generators include:

1. Reliability: Diesel generators are known for their reliability and ability to provide continuous power supply during emergencies. They are designed to start quickly and operate efficiently even in harsh conditions.

2. Fuel Efficiency: Diesel engines are more fuel-efficient compared to gasoline engines, providing more power output for the same amount of fuel. This makes diesel generators a cost-effective option for long-duration backup power.

3. Durability: Diesel engines are built to withstand heavy loads and continuous operation, making them highly durable and long-lasting. With proper maintenance, a diesel generator can last for many years.

4. Easy Maintenance: Diesel generators are relatively easy to maintain compared to other types of generators. Routine maintenance tasks such as oil changes, filter replacements, and fuel system checks can help ensure optimal performance.

5. Quick Start-Up: Diesel generators can start up and reach full power output within seconds, ensuring a seamless transition during power outages. This quick response time is crucial in critical applications where downtime is not an option.

Maintenance Requirements for Diesel Generators

To ensure the reliability and optimal performance of a diesel generator, regular maintenance is essential. Proper maintenance helps prevent breakdowns, extends the lifespan of the generator, and ensures that it is ready to operate when needed. Some key maintenance requirements for diesel generators include:

1. Regular Inspections: Perform visual inspections of the generator, including checking for leaks, loose connections, and signs of wear or damage. Inspect the fuel system, cooling system, electrical components, and exhaust system regularly.

2. Oil and Filter Changes: Change the engine oil and filters at regular intervals as recommended by the manufacturer. Clean oil helps lubricate the engine and prevent friction, while clean filters ensure proper fuel and air flow.

3. Fuel System Maintenance: Keep the fuel tank clean and free of contaminants that can clog the fuel lines or filters. Drain any water or impurities from the fuel tank and replace fuel filters as needed.

4. Battery Maintenance: Check the battery condition and connections regularly to ensure proper charging and starting capacity. Keep the battery terminals clean and free of corrosion to maintain reliable operation.

5. Load Testing: Periodically test the generator under load conditions to ensure that it can handle the required power output. Load testing helps identify any potential issues and ensures that the generator is operating within its rated capacity.

Best Practices for Optimal Performance

In addition to regular maintenance, following best practices can help ensure the optimal performance and reliability of a diesel generator. Some best practices for diesel generator operation include:

1. Regular Testing: Test the diesel generator at regular intervals to ensure that it is in good working condition. Perform start-up tests, load tests, and runtime tests to verify that the generator can provide the required power output.

2. Fuel Quality: Use high-quality diesel fuel that meets the specifications recommended by the generator manufacturer. Proper fuel quality is essential for the reliable operation of the generator and can prevent fuel-related issues.

3. Environmental Considerations: Place the diesel generator in a well-ventilated area with adequate airflow to prevent overheating. Ensure that the generator is protected from moisture, dust, and other environmental factors that can affect its performance.

4. Emergency Preparedness: Develop an emergency response plan that outlines the procedures for activating the generator during power outages. Train personnel on how to start, operate, and monitor the generator safely and effectively.

5. Professional Service: Engage qualified technicians or service providers for routine maintenance, repairs, and troubleshooting of the diesel generator. Professional service can help identify and address issues early, preventing costly breakdowns.

Conclusion

Diesel generators play a critical role in enhancing system reliability by providing backup power during grid outages or emergencies. Their reliability, durability, and efficiency make them a popular choice for a wide range of applications where uninterrupted power supply is essential. By following proper maintenance practices, monitoring performance, and ensuring fuel quality, diesel generators can deliver reliable power when needed. As technology continues to advance, diesel generators are likely to remain a key component in ensuring system reliability and continuity of operations across various industries.